The facility, built in 14 months, tells the story of Mapei in all its areas. The Mapei Football Center was built using products from the company’s extensive range of products and systems.

Both the roof and the underground areas of the main building, for example, were waterproofed using Polyglass systems. While for the roof over the spectator stand the choice went to the maximum in elasticity offered by PURTOP waterproofing systems.

The MAPEPLAN T line was used to waterproof the roofs. Made by Polyglass, a subsidiary of the Mapei Group, MAPEPLAN T is a line of synthetic waterproofing membranes which, thanks to exclusive “multi-extrusion coating” technology, is also able to supply high performance FPO/TPO membranes and features high level of durability, excellent workability and good weldability. The main roof was made using the high reflectance “cool roof” system, consisting of the following layers: POLYVAP FIX vapour barrier, with POLYVAP FIX AL in the more critical areas, PUR/PIR insulating panels and membrane.

MAPEPLAN T Af BRoof (t2) membrane was bonded with MAPEPLAN ADS 100 and MAPEPLAN ADS 310 adhesives. The terraces were waterproofed with MAPEPLAN T B. All the waterproofing operations were completed by using accessories belongining to the MAPEPLAN T line.

To waterproof the retaining walls of the main building and the spectator stand, Polyglass products were used: POLYPRIMER HP 45 PROFESSIONAL bituminous primer, EASY LIFT plastostyrene waterproofing membrane, POLYFOND KIT DRAIN protection and drainage system. The waterproofing system and the POLYFOND KIT DRAIN vertical drainage system were protected with HDPE geocomposite.

The MAPEFLOOR System and ULTRATOP System lines, on the other hand, in combination with TOPCEM screeds were used to finish off the internal areas of the sports centre. And what else other than KERAFLEX MAXI S1 and KERAPOXY to install and grout ceramic tiling and MAPELASTIC to waterproof the bathrooms.

TOPCEM PRONTO pre-blended, ready-to-use mortar with normal setting and controlled shrinkage, TOPCEM quick drying mortars and MAPECRETE LI HARDENER consolidator were used to make the screeds.

To finish off the seamless flooring in the reception rooms and in other areas of the building, the architect opted for the ULTRATOP SYSTEM, with a special bespoke pattern dedicated to Sassuolo Calcio.

The systems used for the other areas of internal flooring more subject to wear, and where a higher degree of non-slip finish was required, were MAPEFLOOR I 320 SL CONCEPT self-levelling, abrasion-resistant epoxy coating with a coloured granular effect finish and the multi-layered MAPEFLOOR SYSTEM 32 for industrial floors, which has high resistance to chemicals, including aggressive chemicals. It is also resistant to wear caused by wheeled vehicles and has a non-slip finish. The MAPESILENT system was applied to guarantee a good level of acoustic comfort, which consisted of MAPESILENT COMFORT sheet, MAPESILENT BAND and MAPESILENT TAPE.

To install the ceramic tiles in various areas, the products chosen were KERAFLEX MAXI S1 and ELASTOCOLOR adhesives and KERAPOXY and ULTRACOLOR PLUS grouts for joints. The last two products guarantees the highest level of resistance to cleaning cycles and ensures surfaces maintain a high level of hygiene.

Products from the DURSILITE line were used to finish off the surface of internal walls, available in an extensive range of colours from the Mapei Master Collection.

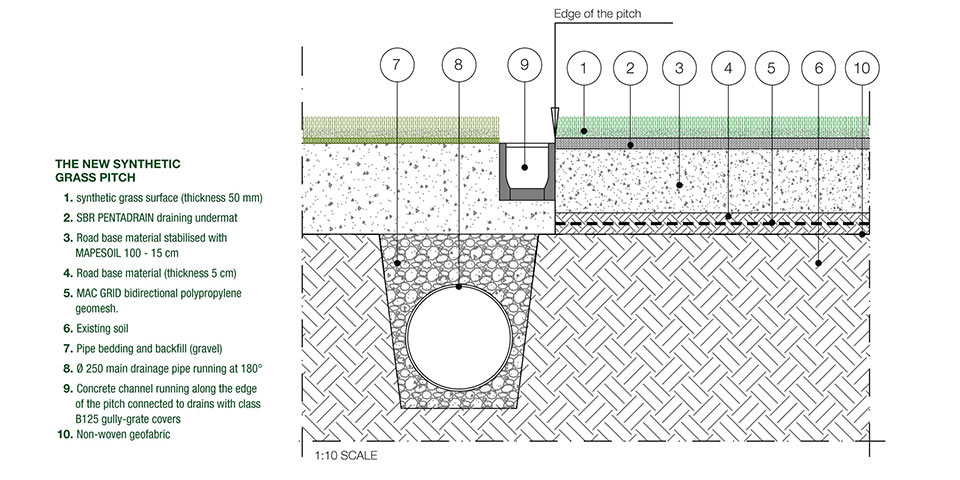

For the drainage system for the pitch the products used were MAPESOIL 100 stabilising agent and MAPESOIL VD hydraulic binder. Aggregates and MALTAVISTA mortar by VAGA (a Mapei Group’s subsidiary) were also used for the sub-bases of the football pitches.

The MAPECOAT TNS RACE TRACK system was used to coat the surfaces of the stands and the pedestrian areas (MAPECOAT TNS PRIMER EPW – MAPECOAT TNS RACE TRACK – MAPECOAT TNS PROTECTION).

Lastly, the showers in the changing rooms were dressed with mosaic from the Tanticolori Verde collection (size of tiles 20x20x4 mm) by Mosaico+, a subsidiary of Mapei Group.